▶ TYTANTM CA-B116 for Polyurethane Coatings, Adhesives, Sealants, Elastomers

Polyurethane is produced by the polyaddition reaction of polyisocyanate with polyalcohol (polyol) in the presence of catalyst and other additives.

Many types of catalysts have been used for polyurethane manufacture, such as compounds of tin, mercury and organic amine compounds. The most commonly used is the tin compound. In many applications, metal catalysts are preferred because they are efficient and effective. For decades, organotin was commonly used as the preferred polyurethane catalyst due to its high activity and good compatibility in most formulations. However, these catalysts, are not favored due to increasing regulatory awareness. This has driven the formulators to search for non-tin alternatives.

TYTAN CA-B116 is a bismuth-based catalyst used for curing a wide range of polyurethane formulations. TYTAN CA-B116 provides much reduced environmental concern and toxicity with higher selectivity and less gassing in the presence of moisture. They are recommended in the area of coatings, adhesives, sealants and elastomers (C.A.S.E.). Furthermore, TYTAN CA-B116 can be used in both one and two component formulations for both ambient cure and heat cure systems.

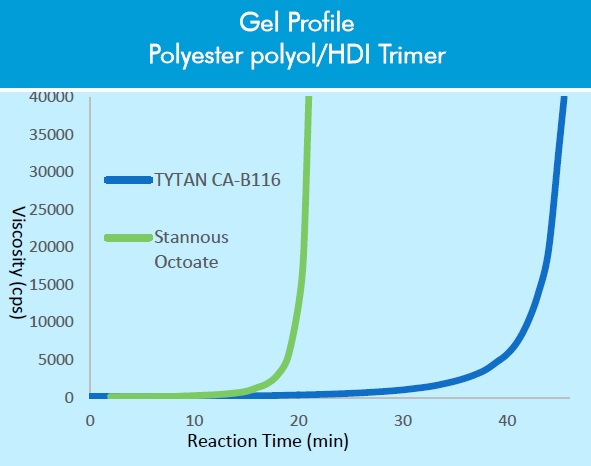

The graph on the right depicts the comparison of the gel profiles between TYTAN CA-B116 and the Stannous Octoate in the formulation of polyester polyol and HDI trimer under the same amount of metal dosage. The reaction rate for TYTAN CA-B116 is moderate with similar profiles as organotin.

Reaction condition:

Dosage: 300ppm of metal

Solid content: 70%

Reaction temp: 80℃

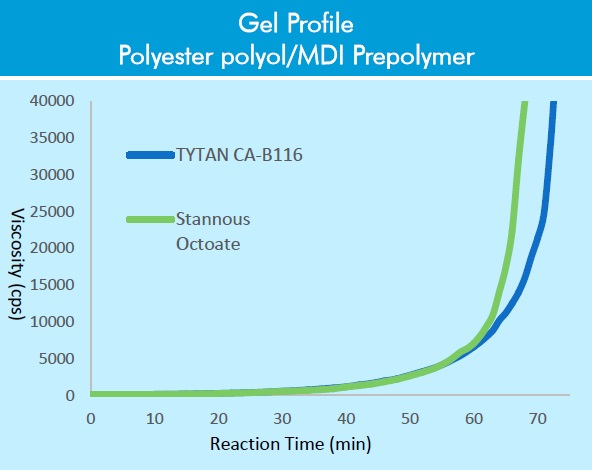

On the other hand, reactivity of TYTAN CA-B116 and Stannous Octoate are comparable in the formulation of Polyester polyol/MDI prepolymer in certain condition.

Reaction condition:

Dosage: 100ppm of metal

Solid content: 70%

Reaction temp: 80℃

Solvent: Ethyl acetate

▶ TYTAN TM range for PU Catalysts

| Product Name | Composition | Features |

| TYTANTM CA-B116 | PU Resin: 100 ~ 500 ppm

TPU: 10 ~ 50 ppm

PU Coating: 500 ~ 1000 ppm | Bismuth Neodecanoate.

16% Bi

Reaction profile similar to organotin

Works well with secondary alcohols

No foam formation in the low level of moisture |