TYTAN

TM, manufactured by Borica Co., Ltd. from Taiwan, is acknowledged as a leader in solvent borne adhesion promoters used in flexible packaging inks. Borica is committed to providing printing ink producers and the packaging industry, with a complete range of high quality, competitive products.

In the past, adhesion promoters have typically been based on titanium and Borica’s current range of titanates strongly improve the adhesion of printing inks to flexible and metal packaging films, while enabling them to withstand heat sealing, freezer storage, abrasive handling, solvents, acids, greases during printing, packaging, storage and handling by consumers.

This range includes TYTAN

TM AP100, the global standard for flexible food packaging adhesion promoter that is fully registered in Europe and the USA.

However, there has been a growing use of Zirconium Propionate (ZPP) in both flexographic and gravure inks, where adhesion to difficult substrates has not been easily achieve with titanates. It is claimed that ZPP offers advantages over the titanates with regards to improved adhesion and resistance to yellowing, especially in inks based on cellulose acetate based polymers (CAB/CAP).

The mechanism for adhesion and crosslinking performance is similar to that used by the titanates. However, ZPP is renowned for having a strong smell and is supplied in solid form and requires dissolution in solvent.

Borica has now developed a proprietary technology platform that provides a very cost effective zirconium based product that delivers excellent adhesion and ink stability performance without the handling issues of ZPP.

This technology platform will allow for a range of zirconium and titanium products to be launched which will provide significant benefits to the ink formulator. Our first product is TYTAN

TM AP910.

TYTAN

TM AP910 is an ethyl citrate zirconium that can be formulated as an adhesion promoter for printing inks, crosslinker for paints as well as a catalyst for esterification.

Due to its proprietary chelated structure, Tytan AP910 shows delayed reaction at ambient temperature and thus facilitates storage stability of inks. Compared with organo-titanate adhesion promoters, it shows good compatibility with PVB, CAB and CAP inks and provides minimal discoloration during the sterilizing process in the printing of milk pouches. As the temperature increases above 60oC, the zirconate can interact with functional groups such as -OH, -COOH, -NH2 in the polymer or substrate that have been provided through corona discharge. This crosslinking provides improved adhesion and further crosslinking with similar functional groups within the resin, provide improved resistance properties.

To demonstrate these benefits, TYTAN

TM AP910 has been evaluated with TYTAN

TM TAA, AP100 and a competitive ZPP at 2.5% loading in the following standard ink formulation.

| Compound | Weight[g] |

|---|

| Ethanol | 114 |

| Ethyl acetate | 171 |

| Nitrocellulose | 60.5 |

| TiO2 | 175 |

| VariPlus SK | 12 |

| PU resin | 85 |

Nitrocellulose: TNC SS 1/8.

PU Resin: Morchem TP629

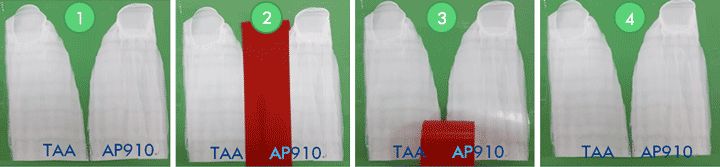

| TAA vs AP910 |

|---|

|

AP910 performs similar adhesion performance with TAA and no yellowish in the ink product.

|

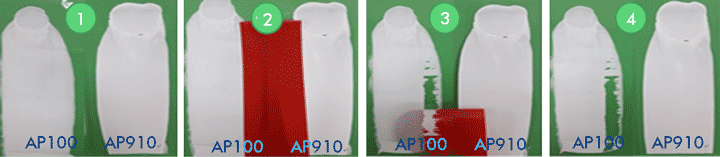

| Ap100 vs AP910 |

|---|

|

AP910 performs much better adhesion performance than AP100, and it’s Acetylaceton-ate and Phosphate ester free.

|

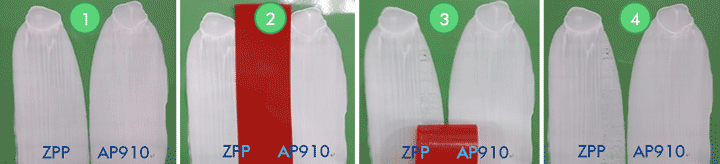

| ZPP vs AP910 |

|---|

|

AP910 performs similar adhesion performance with ZPP. But no solvent needed and no strong smell.

|